WHAT IS INVOLVED IN AN ELECTRICAL THERMOGRAPHIC SURVEY?

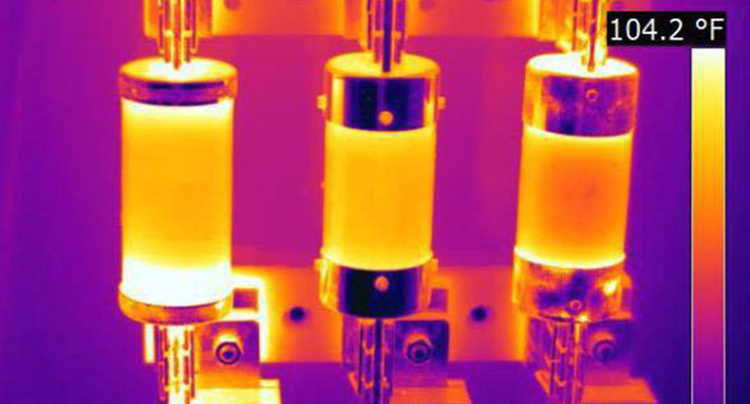

AS Power Engineering Ltd offer infrared thermographic surveys which can predict poor connections, imbalanced loads, overloaded circuits and failing components. This can be effective at fault finding prior to component failure to reduce plant downtime and loss of production.

Our comprehensive thermographic surveys can be carried out on different types of equipment including:

- Busbar systems

- Distribution boards and fuse boards

- Transformers

- Control panels

- Batteries

- Switchgears and switchboards

A thermal imaging survey is an extremely cost effective form of inspection. This can be used to identify both mechanical and electrical faults caused by an increase in heat due to friction or increased resistance.

WHAT ARE THE BENEFITS OF A THERMOGRAPHIC SURVEY?

- Prevention of emergency maintenance

- Fewer business interruptions from equipment downtime

- Minimal potential damage to equipment and facilities

- Formal comprehensive reports that not only locate the problem with extreme precision but also recommend cost-effective solutions

- Improved overall productivity